fhwa steel box girder For this steel girder design example, a plate girder will be designed for an HL-93 live load. The girder is assumed to be composite throughout. Refer to Design Step 1 for . At The Federal Group USA, we produce a diverse range of products and assemblies via metal fabrication including electrical, industrial, medical, structural metal parts, information technology, commercial metal products, mining, signage, transportation, and construction, just . See more

0 · twin box girder diagram

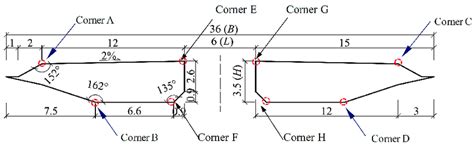

1 · steel trapezoidal box girder

2 · steel girder overhang width

3 · steel girder design examples

4 · steel girder bridge design

5 · steel box girder design

6 · box girder design guide

7 · box girder bridge design guide

This article provides a detailed view of the various methods used in welding sheet metal, including their advantages and applications. It also provides vital tips to note when welding thin sheets of metal to obtain the best outcomes.

For this steel girder design example, a plate girder will be designed for an HL-93 live load. The girder is assumed to be composite throughout. Refer to Design Step 1 for .I-Girder Bending Component Tests. Philosophy and Design of the I-Girder .I-Girder Bending Component Tests. Philosophy and Design of the I-Girder Bending Component Tests (.pdf) (July, 2019) Proposed LRFD Specifications for Noncomposite Steel Box-Section .

The first design step is to identify the appropriate design criteria. This includes, but is not limited to, defining material properties, identifying relevant superstructure information, .This design example illustrates the design calculations for a curved steel I-girder bridge, considering the Strength, Service, Fatigue and Constructability limit states in accordance with .This design example illustrates the design calculations for a curved steel tub girder bridge, considering the Strength, Service, fatigue and Constructibility Limits States in accordance with .

Factor Design (LRFD) to highway bridge design. One design example is a two-span steel plate girder bridge, and the other is a two-span prestressed concrete girder bridge with simple span .girder bridges offer advantages over other superstructure types in terms of span range, stiffness, durability, and future maintenance. This design example demonstrates the design of a tangent .

This document consists of a comprehensive steel girder bridge design example, with instructional commentary based on the AASHTO LRFD Bridge Design Specifications (Second Edition, .Design Examples for Steel Box Girders. The Proposed Design Specifications for Steel Box Girder Bridges as contained in Report No. FHWA-TS-80-205 are evaluated. The results of .review and coordination with FHWA. – Bridge Layout – Steel straddle bent cap plan sheets or steel twin tub girder plan sheets – Steel straddle bent cap or steel twin tub girder design calculation package meeting the requirements of AASHTO Chapter 6, including the calculations demonstrating redundancy. Include explanation of assumptions for

twin box girder diagram

FHWA/TX-19/0-6862-1. Authors: Stalin Armijos-Moya [and five others] Published: 2019. Austin, Texas. University of Texas at Austin. Center for Transportation Research . Steel trapezoidal box girders, generally referred to as tub girders, have been widely used on a number of bridges throughout the State of Texas. The smooth profile of the . LRFD Steel Girder SuperStructure Design Example Bolted Field Splice Design Example Design Step 4 Table of Contents Design Step 4.1 - Obtain Design Criteria Design Step 4.2 - Select Girder Section as Basis for Field Splice Design Design Step 4.3 - Compute Flange Splice Design Loads Design Step 4.4 - Design Bottom Flange Splice Design Step 4.5 - Design .maintained by the Federal Highway Administration (FHWA) Office of Bridges and Structures as FHWA Report No. FHWA-IF-12-052 published in November 2012, and FHWA Report No. FHWA-HIF-16-002 . that differentiate curved steel girders from their straight counterparts include the effects of torsion, flange lateral bending, their inherent lack of . b. FHWA will use Table 1 to determine if procedures developed by Agencies to determine that a steel member fully or partially in tension has system or internal redundancy are consistent with the requirements of 23 CFR 650.313(f)(1)(i). c. FHWA considers the American Association of State Highway and Transportation Officials (AASHTO)

Critical Steel Box-Girder Bridges completed FHWA Memo. Clarification of Requirements for Fracture Critical Members. Introduction of SRM term. Texas Steel Quality Council March 12, 2021. 2012 FHWA Memo What if we can design new twin tub girder bridges to be system redundant?The Federal Highway Administration’s Office of Bridges and Structures released the the final report, Guide for Orthotropic Steel Deck Level 1 Design (Publication No. FHWA-HIF-22-056). The following is an excerpted foreword from Joseph L. Hartmann, PhD, P.E., Director, Office of Bridges and Structures

2.1 Task 1 - Analysis and Design of Large Scale Plate Girder and Box Girder Test Assemblies 5 2.2 Task 2 - Special Studies 11 2.3 Task 3 - Fatigue Tests of Curved plate Girder and Box Girder Test Assemblies 18 2.4 Task 4 - Ultimate Load Tests of Curved Plate and Box Girder Assemblies 20 2.5 Task 5 - Design Recommendations 20 3. FINDINGS

HORIZONTALLY CURVED STEEL BOX GIRDER BRIDGE FINAL REPORT Prepared for National Cooperative Highway Research Program Transportation Research Board National Research Council . As a result of the research work on curved bridges conducted by the FHWA and several research institutes, design provisions for both straight and curved bridges were . About Press Copyright Contact us Creators Advertise Developers Terms Privacy Policy & Safety How YouTube works Test new features NFL Sunday Ticket Press Copyright .ASCE-AASHTO Subcommittee on Ultimate Strength of Box Girders, chaired by C.G. Culver, for their prior work on reviewing the state of the art of box girder bridge de sign (G97, G39, G40). Work on this project was carried out under the guid--- ance of the ASCE-TCCS Committee on Steel Box Girder

LRFD Steel Girder SuperStructure Design Example Pier Design Example Design Step 8 Table of Contents Design Step 8.1 - Obtain Design Criteria Design Step 8.2 - Select Optimum Pier Type Design Step 8.3 - Select Preliminary Pier Dimensions Design Step 8.4 - Compute Dead Load Effects Design Step 8.5 - Compute Live Load Effects Design Step 8.6 - . Hi, If anyone has experience with designing steel box giders and would be able to share any helpful references, it would be hugely appreciated. The design is not for a bridge, although many of the resources I have found so far are geared towards bridge design and have still been helpful.

Guide for Heat-Straightening of Damaged Steel Bridge Members, FHWA Report No. FHWA-IF-08-999 . The bridge has twin Eastbound and Westbound superstructures consisting of two variable depth steel box girders with an orthotropic steel deck on a shared substructure. A unique aspect of the project was the sliding of the existing bridge to increase .The construction of horizontally curved steel bridges is generally more complex than the construction of comparable straight-girder bridges of similar span. Curved-girder bridges, once completed, h.

steel trapezoidal box girder

In these cases, straight steel box girders are used in regions where the clear span requirements preclude the use of the concrete U-beams. 17. . Two-Span Continuous Straight Composite Steel I-Girder Bridge Publication No. FHWA-IF-12-052 - Vol. 21 November 2012 Archived Archived Technical Report Documentation Page 1. Report No. 2. Government .Composite steel-concrete box girders are commonly used in curved bridges, interchanges, and ramps. Curved composite box girders have a number of unique qualities that make them . (FHWA). A new Curved Steel Bridge Research (CSBR) project is currently being conducted under the auspices of the FHWA. Although the CSBR project is expected to .numerous components of a steel tub girder bridge (girders, internal and external diaphragms, lateral bracing members, stiffeners, bearings, deck, field splices, etc.); suggestions on steel tub girder detailing; and special considerations for construction of a steel tub girder bridge. While this book is not a stand-alone steel tub[FHWA is] working with partners in the steel industry to coordinate and develop robotics and automation for steel fabrication, which will ensure high-quality shop production, rapid deployment, and lower life-cycle cost. . Between 1969 and 1971, four box girder bridges in Europe and Australia collapsed. High-performance steel has improved .

of cast-in-place concrete box-girder superstructures. Material characteristics of the concrete and prestressing steel are presented in Chapter 2 of the manual. Pertinent time-dependent characteristics in accordance with the CEB-FIP Model Code (1990) of New FHWA Post-Tensioned Box Girder Design Manual all tub and box girders to be painted with a-light colored paint (white polyamide cured epoxy) to facilitate crack . Suggest dapping if difference in approach span depth and steel girder depth is >1.5’ for aesthetic reason (Will remain in document). . New language will allow design for system redundancy per FHWA June 2014Report No. FHWA-TS-80-205 a:::.:.. PROPOSED DESIGN SPECIFICATIONS FOR STEEL BOX GIRDER BRIDGES January 1980 Final Report Document is available to the public through . steel box girder bridges, with commentary, in fulfillment of the requirements of Task D, and bibliography, given in Appendix A. Also included in this report are conclu

The post - tensioned Box Girder Design Manual was developed as a part of the FHWA project Advancing Steel and Concrete bridge Technology to Improve Infrastructure Performance. Brian Kozy and Reggie Holt of FHWA are providing direction to the project team led by Lehigh University and that includes Corven Engineering. . New FHWA Post-Tensioned .Select steel girder types Girder spacing Approximate girder depth Check vertical clearance Yes No Return to Main Flowchart Plan for Bridge Aesthetics S2.5.5 Design Step 1.6 Considerations include: Function Proportion Harmony Order and rhythm Contrast and texture Light and shadow Chart 1 Flowcharts Design Example for a Two-Span Bridge FHWA LRFD . Purpose of the Training Tub or box girders are a popular alternative to I-girders for their pleasing appearance; offering a smooth, uninterrupted cross section. Minor superstructure members such as bracing, web stiffeners, utilities and other structural and non-structural components can be hidden from the view within the steel tub/box girder contributing to their .FHWA/TX-07/0-4307-1 2. Government Accession No. 3. Recipient’s Catalog No. 5. Report Date April 2007 4. Title and Subtitle . In these cases, straight steel box girders are used in regions where the clear span requirements preclude the use of the concrete U-beams. 17. Key Words Steel, Box Girders, Trapezoidal, Torsional 18. Distribution .

This tutorial demonstrates the key highlights of the modeling capabilities of midas Civil for a steel plate I-girder composite straight bridge. This tutorial is based on the bridge specifications of the Federal Highway Administration's Steel Bridge Design Handbook Design Example 2A: Two-Span Continuous Straight Composite Steel I-Girder Bridge.

metal music video kids in house

metal octagon ceiling boxes with attaching screws

Below are a few recommendations on how to weld on galvanized steel. Any Arc Welding Process – General Recommendations. The best way to weld galvanized steel, regardless of welding process, is to remove the zinc coating from the joint.

fhwa steel box girder|box girder bridge design guide